High-Capacity, High-Moisture, Fine Particle Reduction with RENN Hammer and Grinder Mills

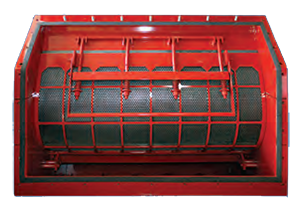

Dairy and commercial livestock operations that require a very fine grind (finer than 1,200 microns) and need to process large volumes of high-moisture grain should look no further than the RENN 22” diameter, full circle Hammer Mill (Grinder).

Offering the same proven durability and performance of our Roller Mills, RENN Hammer Mills (Grinders) feature rigid-mounted, ¼-inch Hardox hammers and interchangeable screens for optimum capacity and excellent grind quality. The screens range in size from 3/32” to 3/8” and are easily interchangeable thanks to a quick-change, spring-loaded, shock-absorbent screen carriage.

Heavy-duty spherical roller bearings and plate magnet hammer protection make RENN Hammer Mills (Grinders) durable and reliable for processing large volumes of grain.

RENN Hammer Mills (Grinders) come with auxiliary PTO auger discharge or conveyor discharge options.

Auxiliary PTO Hammer Mill

The RENN Auxiliary PTO Hammer Mill (Grinder) offers the flexibility of processing grain directly into the bagger. Simply operate the RENN Hammer Mill and Bagger in sequence with one single tractor. RENN has perfected this proven auxiliary system over the past 18 years, providing producers with maximum equipment and manpower efficiency – saving time and money!

Auxiliary PTO Features:

- Heavy-duty PTO with over-running clutch

- Mechanically-driven discharge auger

- Dual-point pivoting, hydraulically-driven feed auger

- 540 or 1000 auxiliary PTO output

Hammer Mill with Conveyor Discharge

The RENN Hammer Mill (Grinder) with Conveyor Discharge is designed for producers who need to process large volumes of high-moisture grain into a fine grind with speed and ease. The smooth and gentle movement of the conveyor allows the finely ground product to be transferred for bunker storage without the assistance of air – protecting your valuable commodity from blowing away.

Conveyor Discharge Features:

- Heavy-duty PTO with over-running clutch

- 18” mechanically-driven discharge conveyor

- Dual-point pivoting, hydraulically-driven feed auger

Hammer Mill/Grinder Specifications:

Model RH - A 2248

| Mill Size DxW | 22" x 48" |

| Screen Area | 2784 sq/in |

| Hammers | 140 |

| Shaft Dia. | 2 15⁄16" |

| Max HP | 300 |

| PTO | 1000 |

| Feed Auger | 12" auger |

| Discharge | 14" auger |

| Capacity (HM Corn) |

3400 bu/hr |

Model RH - C 2248

| Mill Size DxW | 22" x 48" |

| Screen Area | 2784 sq/in |

| Hammers | 140 |

| Shaft Dia. | 2 15⁄16" |

| Max HP | 300 |

| PTO | 1000 |

| Feed Auger | 12" auger |

| Discharge | 18" conveyor |

| Capacity (HM Corn) |

3400 bu/hr |

Model RH - A 2236

| Mill Size DxW | 22" x 36" |

| Screen Area | 2088 sq/in |

| Hammers | 105 |

| Shaft Dia. | 2 15⁄16" |

| Max HP | 250 |

| PTO | 1000 |

| Feed Auger | 10" auger |

| Discharge | 12" auger |

| Capacity (HM Corn) |

2550 bu/hr |

* Maximum rated capacity for 28% moisture corn. Capacity will change with moisture content, screen size, and horsepower provided.

Contact RENN or one of our knowledgeable distributors, and let us help you choose a RENN Hammer Mill optimized to match your exact grain processing requirements.

Equipment specifications subject to change without notice.